ElaProof+SAND Floor Covering – Technical information

ElaProof+SAND Floor Covering is suitable for indoor and outdoor use

Binding agent: waterborne polymer dispersion

Colours: white, grey, dark grey and black – Can be painted over with most water-based, breathable and elastic paints.

Surface varnishing: We recommend ELACOAT TopCoat treatment for surfaces that are heavily trafficked and require easy cleaning.

Sand grain sizes:

• Fine (0,05-0,2 mm)

• Medium (0,1-0,6 mm)

• Rough (0,7-1,2 mm)

Product selection: coating to be applied with a trowel

Base materials: all building materials, e.g. concrete, masonry structures, cement-based screeds, tiles*), building boards (chipboard, plasterboard), plastic and bathroom floors and walls coated with different materials

Dry matter content: 81 ± 1 %

Acidity (pH): 7-8

Density: 1,60 ± 5 g/cm3

Recommended dry film thickness:

• Floors min. 2,0 mm

Water vapor permeation: 20 ± 1 g / m2 / day

Fire class: A2 FL

Adhesion strength, without primer: 1 – 4 N/mm2

Operating temperature: over +10°C

Drying time: (+20°C, 50% RH, 2,0 / 4,0 kg/m2) 12 h

Emission classes::

• M1 • Eurofins, Finland, 2023

Storage time: min. 12 months (see package for manufacturing date)

Storage: Product must not freeze. Protect for direct sunlight.

Temperature resistance

• Long term: -30°C … +150°C

• Short term: max. +190°C

Weather resistance (UV, thermal and moisture resistance): excellent

Electrical conductivity: does not conduct electricity

*) The tiled floor of the bathroom must be waterproofed with an approved waterproofing material intended for use under ceramic tiles. This waterproofing must not be more than 10 years old at the coating stage, based on RIL 107-2012 guidelines

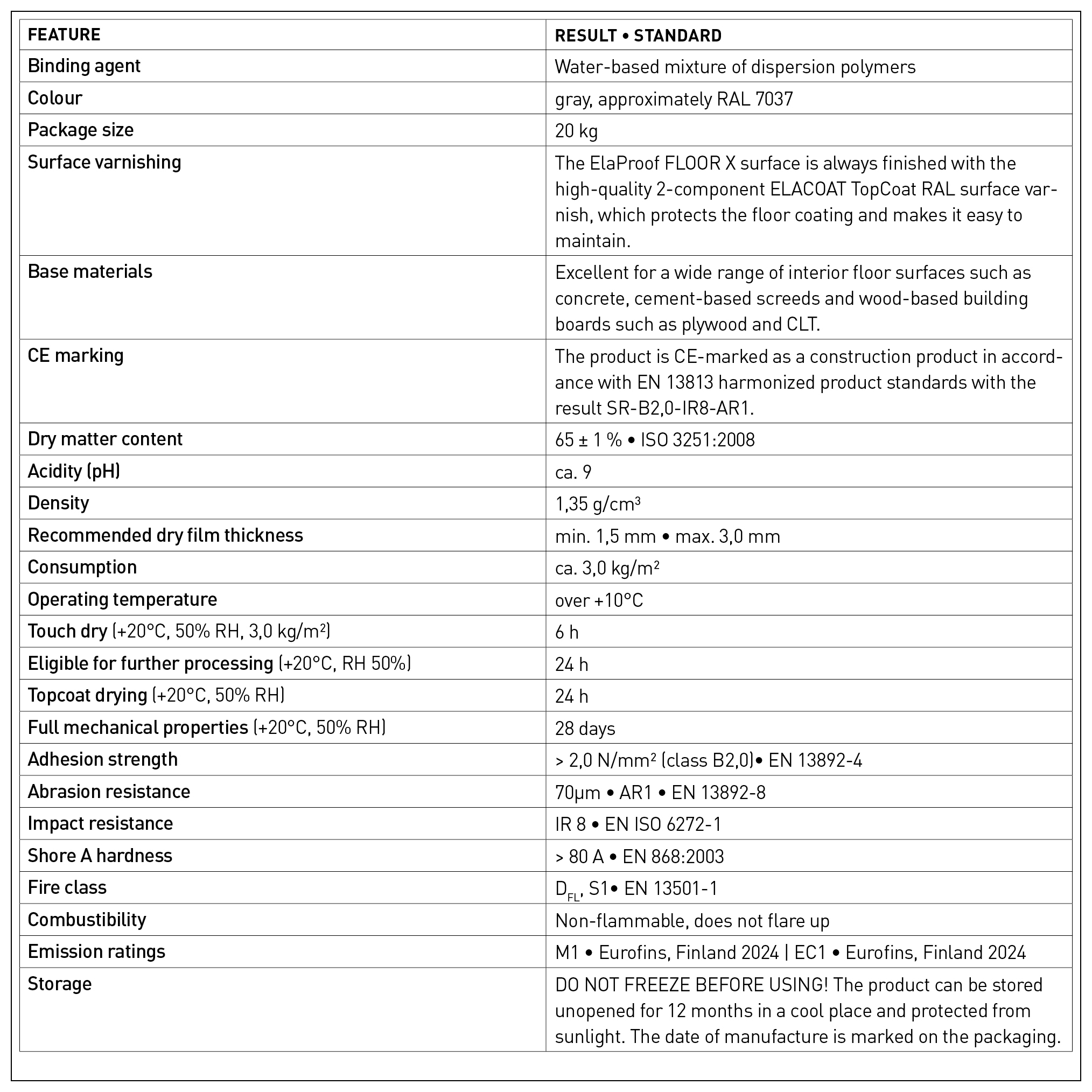

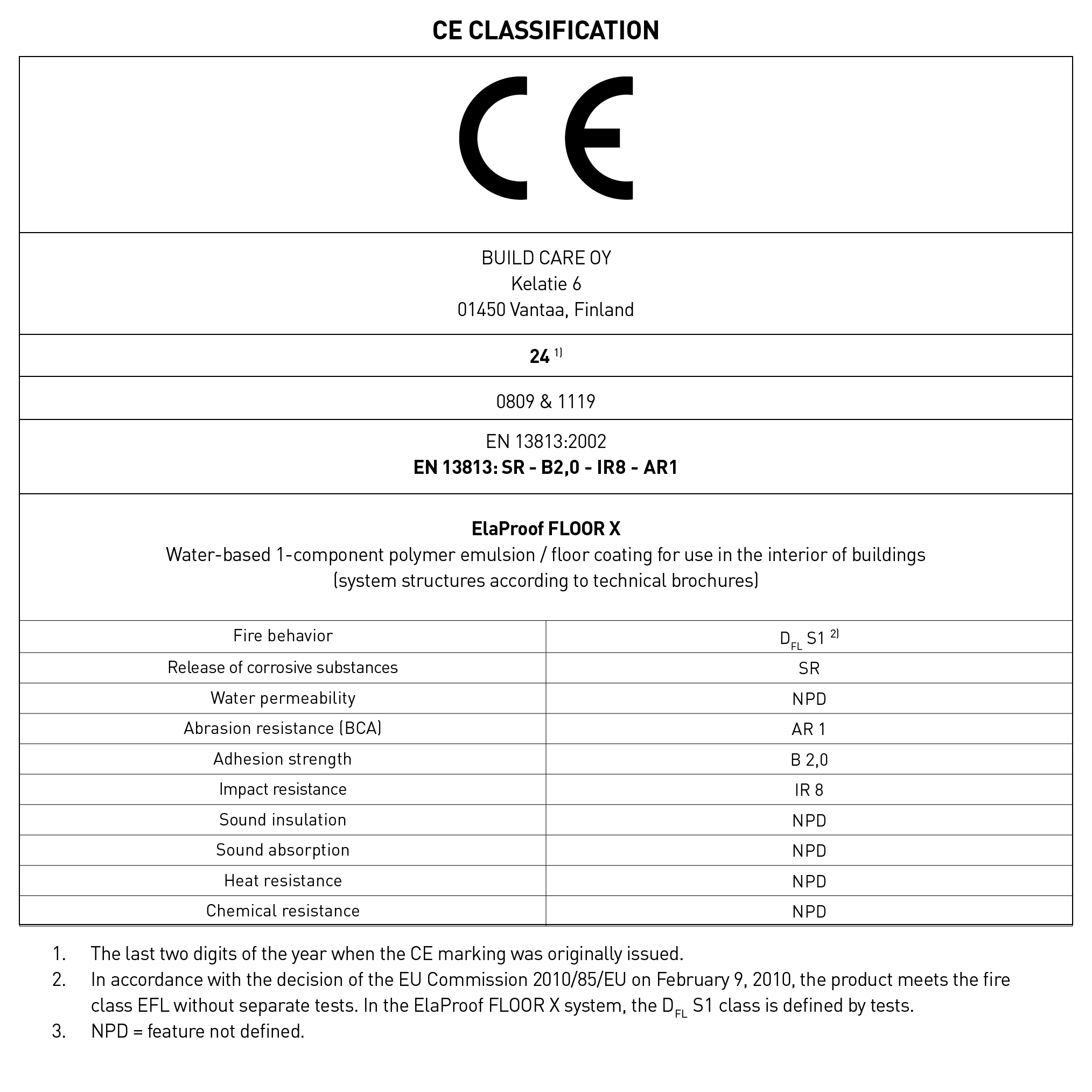

ElaProof FLOOR X – Product Data Sheet

Applications

The ElaProof FLOOR X coating is suitable for use in e.g. warehouses, classrooms, offices and living spaces. The base material can be concrete, chipboard or plasterboard. Concrete substrates should always be levelled with a screed suitable for the purpose, with a strength class of at least C30, F7 classified according to the EN 13813 standard.

Product description

ElaProof FLOOR X is a water vapor permeable, elastic floor coating for indoor use with self-smoothing properties. ElaProof Floor X is a CE-marked construction product based on testing according to the EN 13813 standard. ElaProof FLOOR X floor coating is always treated with ELACOAT Top Coat or ELACOAT Top Coat RAL topcoat, which forms the final tread surface of the system. The final surface of the system has a pleasant soft feel when working while standing for a long time, the elastic properties of the system also have a positive effect on the acoustics of the coated space, reducing echoes in the space.

The final surface structure of the ElaProof FLOOR X coating can be influenced by intermediate sanding before surface varnishing, so that the surface becomes completely flat and smooth. If necessary, the surface can also be left unsanded and varnished directly after drying with a surface varnish, leaving a little structure created by the work tools on the surface, e.g. reducing the risk of slipping.

Colors and packaging

Grey, ca. RAL 7037 • 20 kg

Characteristics

• Water vapour-permeable, self-smoothing floor coating

• Bio-based product – ecological choice

• Isocyanate- and phthalate-free product

• M1 emission classification and Emicode EC1

Cleaning and maintenance

Cleaning and maintenance of the ElaProof FLOOR X floor finished with ELACOAT TopCoat varnish can be done with these instructions!

Technical support

Tel. +358 20 790 2710 • e-mail: info@buildcare.fi

Technical information

Installation

Preliminary work before starting the coating

The product is suitable for use on most floor surfaces for indoor use. The floor surface can be e.g. chipboard, plasterboard and concrete. Concrete platforms must first be levelled with a floor leveller suitable for the purpose. The strength of the screed is at least C30, F7 as classified according to standard EN 13813. Before starting the coating work, familiarize yourself with the preliminary work required by the surface material of your site. Please download suitable coating work proposal here!

Conditions

The most recommended installation conditions are +15–20°C, RH 50% air relative humidity. Direct sunlight on the coating area must be avoided, as well as drafty conditions. Lower temperatures and high relative humidity significantly slow down the drying of the product. Correspondingly, high temperatures accelerate the drying of the product and may cause harm to the self-smoothing properties of the product. Non-absorbent base materials also significantly affect the drying time, lengthening it.

- Minimum installation temperature + 10°C in air and on the substrate.

- Maximum installation temperature +25°C in air and on the substrate.

- Maximum air relative humidity 75% RH.

- Maximum substrate relative humidity 90% RH.

Priming:

Surfaces to be coated are primed with ElaProof Primer before coating. Porous and absorbent surfaces are primed with ElaProof Primer diluted 1:2 (1 part primer:2 parts water). Repeat the priming, if necessary, if the applied primer is absorbed into the substrate in an instant. The coating can be applied as soon as the primer has dried. Ponds must not appear!

Moisture-sensitive substrates, such as wood-based building boards and plasterboards, are primed with undiluted ElaProof Primer. In this case, let the primer dry for at least 12 hours before starting the coating.

Coating:

Mix ElaProof Floor X Floor Coating before use. Use a wire whisk in the mixer, which does not introduce air into the sealing compound during mixing. ElaProof Floor X Floor coating is applied to the substrate with a toothed steel trowel intended for self-leveling floor products, e.g. E.Vuorio Oy product no. 4649 in one application. After application, the coating is treated with a spike roller, e.g. E.Vuorio Oy product no. 7814. ElaProof Floor-X consumption should be approx. 3.0 kg/m2 and the realized dry film thickness should be min. 1.5 mm. On absorbent substrates, the ElaProof Floor X floor coating can be further processed after approx. 24 h under conditions of +20°C, 50% RH. On non-absorbent substrates, suitability for further processing may require a longer time. NOTE! If necessary, the product can be thinned by a maximum of 1 percent by weight (2 dl for a 20 kg container). If you are diluting the product, start with a small amount of water and add more if necessary. Adding too much water to the product may have a weakening effect on the product’s technical properties!

Intermediate sanding:

If you want the surface of the ElaProof Floor X floor coating to be completely smooth and even, perform intermediate sanding with a floor sander before varnishing the surface. Use a 40-grit sandpaper disc in the floor sander and sand the coated floor completely smooth. Vacuum the resulting lint with an industrial vacuum cleaner.

Varnishing:

The dried ElaProof Floor X floor coating is treated with clear ELACOAT TOPCOAT or tinted ELACOAT TOPCOAT RAL topcoats to facilitate cleaning and maintenance. For floors that remain in one colour, we recommend topcoating with tinted ELACOAT TOPCOAT RAL topcoat to even out possible colour differences in the ElaProof Floor X floor coating. Mix the topcoat according to the instructions on the package. Apply the topcoat over the dried ElaProof Floor X coating with a short-pile roller (6-7 mm) by rolling it crosswise. The consumption of the surface varnish is approx. 110-200 g/m2/application. The surface varnish is dry to the touch after approx. 16 hours in conditions of + 20°C, 50% RH. The full duration of mechanical stress is reached in the above conditions after approx. 4 days, and the full chemical duration after approx. 7 days. NOTE! Some colours of ELACOAT TOPCOAT RAL topcoats may require 2-3 treatments to achieve sufficient coverage! See the separate table for coverage of ELACOAT TOPCOAT RAL topcoats.

Structural drawings:

You can find all structural drawings related to ElaProof products in DWG and PDF format in the ProdLib-service.

Updated: 05/2024 | MA

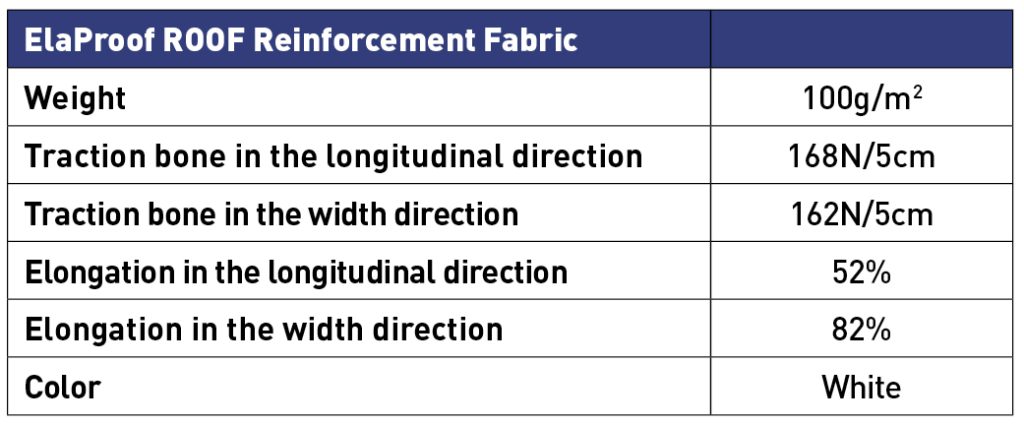

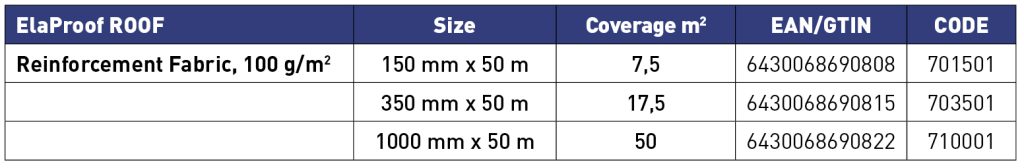

ElaProof ROOF Reinforcement Fabric – Technical information

ELACOAT TopCoat RAL – Technical Information

ELACOAT TOPCOAT RAL is a water-based, pigmented, silk-matte 2-component topcoat based on high-quality, aliphatic and low-emission PU resin. The product is used as a top coat over the elastic ElaProof coating. A surface varnish provides a more durable and easier-to-maintain surface for the floor. The product can also be used like paint on e.g. concrete floors or wall surfaces that require special durability.

ELACOAT TOPCOAT RAL is colorfast and weather-resistant. It is resistant to fuels and lubricating oils, most solvents and many other chemicals. Stains may remain on the surface varnish during some exposures, but they do not affect the technical properties of the surface varnish. Depending on the installation method, a fine structure may appear in the surface varnish, which does not, however, affect the technical properties of the surface varnish. We recommend doing a trial coating before starting the actual work.

When applying bright or colorful shades, we recommend applying two layers to increase coverage. It would also be desirable for the material below to be close to the same tone.

Package size:

- 3,375 kg (3 kg A-component and 0,375 kg B-component)

- 9 kg (8 kg A-component and 1 kg B-component)

Mixing ratio: A:B 100:12,5

Consumption: 90–200 g/m2, depending on the roughness of the substrate

Working time: ca. 60 min after mixing the components

Working temperature: +15–25 °C (min 3 °C above the dew point)

Permissible air relative humidity during work: 40–75 % RH

Walkable: ca. 16 h (+ 20 °C)

Completely stress-resistant:

- mechanical 4 days (+ 20 °C)

- chemical 7 days (+ 20 °C)

Viscosity: n. 700–1500 Mpas

Density: ca. 1,1 g/cm³

Color: several colours

Storage period: 12 months in unopened original packaging

Storage: +10–25 °C in dry place, avoid direct sunlight, protect from freezing

01/2023 | MA

ELACOAT TopCoat – Technical Information

ELACOAT TOPCOAT is a water-based, clear, silk-matte 2-component topcoat based on high-quality, aliphatic and low-emission PU resin. The product is used as a top coat over the elastic ElaProof coating. A surface varnish provides a more durable and easier-to-maintain surface for the floor.

ELACOAT TOPCOAT is colorfast and weather-resistant. It is resistant to fuels and lubricating oils, most solvents and many other chemicals. Stains may remain on the surface varnish during some exposures, but they do not affect the technical properties of the surface varnish. Depending on the installation method, a fine structure may appear in the surface varnish, which does not, however, affect the technical properties of the surface varnish. We recommend doing a trial coating before starting the actual work.

NOTE! A clear topcoat does not prevent the material below from yellowing, in which case a pigmented, aliphatic topcoat is necessary.

Package size:

- 3,3 kg (3 kg A-component and 0,3 kg B-component)

- 11 kg (10 kg A-component and 1 kg B-component)

Mixing ratio: A:B 100:10

Consumption: 90–200 g/m2, depending on the roughness of the substrate

Working time: ca. 60 min after mixing the components

Working temperature: +15–25 °C (min 3 °C above the dew point)

Permissible air relative humidity during work: 40–75 % RH

Walkable: ca. 16 h (+ 20 °C)

Completely stress-resistant:

- mechanical 4 days (+ 20 °C)

- chemical 7 days (+ 20 °C)

Viscosity: n. 700–1500 Mpas

Density: ca. 1,1 g/cm³

Color: clear silk mat

Storage period: 12 months in unopened original packaging

Storage: +10–25 °C in dry place, avoid direct sunlight, protect from freezing

01/2023 | MA

ElaProof Indoor H / PRO S Technical specification

Specification (wet product) • Standard / Method

- Binding agent: waterborne polymer dispersion

- Colours: black, grey and white – can be painted over*)

- The product is CE marked as a construction product in accordance with the harmonized product standards EN 13813 and EN 1504-2

- Products: hand spreadable elastomer, sprayable elastomer

- Adhesion to base materials: all construction materials, e.g. all concrete based, metal, aluminium, construction plates, glass, wowen materials

- Dry matter content: 65,5 ± 1 % • ISO 3251:2008

- Acidity (pH): 8-9

- Recommended dry film thickness:

- ◦ Air sealing min. 0,5 mm

- ◦ Radon barrier min. 0,8 mm

- Operating temperature: over +10°C

- Drying time: (+20°C, 50% RH, 1,0 l/m2) 3 – 4 h (depending on the substrate)

- Adhesion strength: 1-4 N/mm2 (depending on the substrate) • EN 1542:1999, EN ISO 4624

- Elongation at break: 1135 % • ISO 527-1:1993

- Wear resistance: <3000 mg • EN ISO 5470-1 (Taber wear test)

- Impact resistance: class I • EN ISO 6272-1

- Crack bridging ability:

- ◦ 13,9 mm (+22°C, 50% RH, thickness 0,6 mm) • EN 1062-7, method A applying, class A5

- Tear strength: 9,3 ± 1,3 MPa/m² • ISO 527-1:1993

- Water vapor permeation: δ, kg/(m·s·Pa) 1,05·10-13 • EN 12572

- Diffusion resistance, Sd-value: 0,56 • EN 12572

- Fire class: C-s1,d0 • EN 13501-1

- Water permeability: 0.03 kg / m2h, meets class W3 low water permeability • SFS EN 1062-3

- Air tightness: tight • Vahanen Ltd., 2018

- Radon tightness: tight • SP Method 3873, RISE, Sweden, 2017

- Emission classes:

- ◦ M1 – smallest amount of emissions • Eurofins, Denmark, 2019

- ◦ Emicode EC1 – very low emissions • Eurofins, Denmark, 2019

- Storage time: min. 12 months (see package for manufacturing date)

- Storage: Product must not freeze. Protect for direct sunlight.

*) Can be painted over with most water-based, breathable and elastic paints.

Updated: 11/2023 | MA

ElaProof PRO S – Technical information

Specifications (wet product) • Standard

- Binding agent: waterborne polymer dispersion

- Colours: black, white, grey, red, RR11, RR23 and RR32 – can be painted over*)

- The product is CE marked as a construction product in accordance with the harmonized product standards EN 13813 and EN 1504-2

- Dry matter content: 65,5 ± 1 % • ISO 3251:2008

- Acidity (pH): 8-9

- Density: 1,17 ± 0,01 g/cm3 • ISO 2811-1:2016

- Flammability: does not ignite, does not flash

- Minimum Film Formation Temperature (MFFT): < 0°C

- Operating temperature: over +10°C

- Drying time

- ◦ Touch dry (+20°C, 50% RH, 1,5 l/m2) 3 – 4 h

- ◦ Touch dry (+6°C, 25% RH, 1,5 l/m2) 40 h

- ◦ Fully dry (+20°C, 50% RH, 1,5 l/m2) 1 vrk

- ◦ Full mechanical properties (+20°C, 50% RH, 1,5 l/m2) 3 weeks

- Storage time: min. 12 months (see package for manufacturing date)

- Storage: Product must not freeze. Protect for direct sunlight.

*) Can be painted over with most water-based, breathable and elastic paints.

Features (coating) • Standard

- Fire class: C-s1,d0 • EN 13501-1

- Adhesion strength, without primer: 1 – 4 N/mm2 • EN 1542:1999

- Tensile strength: 2,3 N/mm² • ISO 527-1:1993

- Elongation at break: 810 % • ISO 527-2 applying

- Tear strength: 9,3 ± 1,3 MPa/m² • ISO 527-1:1993

- Shore A hardness: 54 ± 4 • EN 868:2003

- Wear resistance: <3000 mg • EN ISO 5470-1 (Taber wear test)

- Impact resistance: class I • EN ISO 6272-1

- Crack bridging ability

- ◦ 10,1 mm (+22°C, 50 % RH, thickness 0,6 mm) • EN 1062-7, method A applying, class A5

- ◦ approved (-20°C, thickness 0,6 mm) • EN 1062-7, method A applying, class A4

- Water vapor permeation: 18 g / m² / day • EN 12572

- Water vapor diffusion coefficient: δ, kg/(m·s·Pa) 9,63·10-13 • EN 12572

- Diffusion resistance, Sd-value: 2,02 • EN 12572

- Water tightness (+20°C, 14 day, 100 mm water immersion): tight • EN 1928

- Temperature resistance

- ◦ Long term: -30°C … +150°C

- ◦ Short term: max. +190°C

- Weather resistance (UV, thermal and moisture resistance): excellent

- Chemical resistance

- ◦ Excellent alkaline resistance

- ◦ Good inorganic acid resistance

- ◦ Limited resistance to organic acids and solvents

- Electrical conductivity: does not conduct electricity

Updated: 10/2024 | MA

ElaProof Classic H – Technical information

SPECIFICATIONS (WET PRODUCT) • STANDARD

- Binding agent: waterborne polymer dispersion

- Colours: black, grey, red, RR11, RR23 and RR32 – can be painted over*)

- The product is CE marked as a construction product in accordance with the harmonized product standards EN 13813 and EN 1504-2

- Dry matter content: 63 ± 1 % • ISO 3251:2008

- Acidity (pH): 7-8

- Density: 1,12 ± 0,3 g/ml • ISO 2811-1:2016

- Flammability: does not ignite, does not flash

- Minimum Film Formation Temperature (MFFT): < 0°C

- Operating temperature: over +10°C

- Drying times:

- Touch dry (+20°C, 50% RH, 1,5 l/m2) 3 – 4 h

- Touch dry (+6°C, 25% RH, 1,5 l/m2) 40 h

- Fully dry (+20°C, 50% RH, 1,5 l/m2) 1 vrk

- Full mechanical properties (+20°C, 50% RH, 1,5 l/m2) 3 weeks

Storage time: min. 12 months (see package for manufacturing date)

Storage: Product must not freeze. Protect for direct sunlight.

*) Can be painted over with most water-based, breathable and elastic paints.

FEATURES (COATING) • STANDARD

- Fire class: C-s1,d0 • EN 13501-1

- Adhesion strength, without primer: 1 – 4 N/mm2 • EN 1542:1999

- Tensile strength: 2,3 N/mm² • ISO 527-1:1993

- Elongation at break: 810 % • ISO 527-2 applying

- Tear strength: 9,3 ± 1,3 MPa/m² • ISO 527-1:1993

- Shore A hardness: 54 ± 4 • EN 868:2003

- Wear resistance: <3000 mg EN ISO 5470-1 (Taber wear test)

- Impact resistance: class I • EN ISO 6272-1

Crack bridging ability

- 10,1 mm (+22°C, 50 % RH, thickness 0,6 mm) • EN 1062-7, method A applying, class A5

- approved (-20°C, thickness 0,6 mm) • EN 1062-7, method A applying, class A4

- Water vapor permeation: 18 g / m² / day • EN 12572

- Water vapor diffusion coefficient: δ, kg/(m·s·Pa) 9,63·10-13 • EN 12572

- Diffusion resistance, Sd-value: 2,02 • EN 12572

- Water tightness (+20°C, 14 day, 100 mm water immersion): tight • EN 1928

- Water resistance after alkaline stress (+70oC, 168 day: 50 mm kyll. Ca(OH)2 solution: tight • EN 1928

Structure tightness

- The water tightness of floor drain and inlets: (Vieser-floor drain, water pressure test 24 h ca. 700 Pa -> +60oC/+15oC, 1500 times -> water pressure test 24h ca. 700 Pa): tight • EN 1253-2

Temperature resistance

- Long term: -30°C … +150°C

- Short term: max. +190°C

- Weather resistance (UV, thermal and moisture resistance): excellent

Chemical resistance

- Excellent alkaline resistance

- Good inorganic acid resistance

- Limited resistance to organic acids and solvents

- Electrical conductivity: does not conduct electricity

Updated: 10/2024 | MA